天津市富通阀门有限公司网站升级上线!

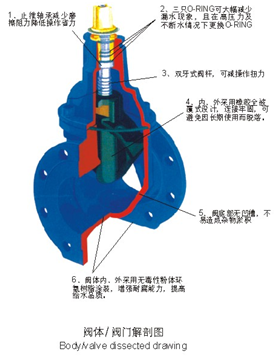

对弹性座封闸阀

Elasticity seals gate valve

●简介 Brief

长期以来市场上使用的一般闸阀普遍存在着;漏水或易生锈现象,本公司引进国外先进技术所生产的弹性座封闸阀,克服了一般闸阀密封性差、弹性疲乏、橡胶老化及生锈等缺陷。软密封闸阀是传统闸阀的换代产品,该阀具有开阀轻巧、密封可靠、弹性记忆佳及使用寿命长等显著优点。可广泛用于自来水、污水、建筑、石油、化工、食品、医药、轻纺、电力、船舶、冶金、能源系统等流体管线上作为调节和截流装置使用。

Snce long ago in the market uses the common gate valve generally has the water leak age or the easy rusty phenomenon, this company introduce elasticity seals gate valve which the over seas advanced technology produces, overcame the common gate valve leak-proof quality bad, elastic fatigue, the rubber got older and rust sand so on the flaw, softly sealed the gate valve is the traditional gate valve update product, had the micro distortion compensation using the elastic damper plate, achieved the good seal effect, this valve had start the valve dexterous, the seal reliable,the elastic memory good and the service life is long and so on the remarkable merit. But widely uses in the running water, the sewage, the building, the petroleum, the chemical industry, food, the medicine, lightly spins, the electric power, the ships, the metallurgy, on the energy system uniform flux body pipeline the achievement adjusts and dams the current the installment use.

●特点 Features

1、重量轻:本阀采用球墨铸铁制造而成,重量较传统闸阀重量减轻20%-30%,安装维修方便,

2、平底式阀座:传统的闸阀往往在通水洗管后卽因外物诸如石头、水块、水泥、铁屑、杂物等淤积于阀底凹槽内,容易造成无法关闭紧密而形成漏水现象。弹性座封闸阀底部采用于水管相同的平底设计,不易造成杂物淤积,使流体畅通无阻。

3、整体包胶:阀瓣采用高品质的橡胶进行整体内、外包胶,国内一流的橡胶硫化技术使得硫化后的阀板能够保证精确几何尺寸,且橡胶与球墨铸铁闸板连接着牢靠,不易脱落及弹性记忆佳。

4、精铸阀体:阀体采用精密铸造,精确的几何尺寸使得阀体内部无需任何精加工即可保证阀门的密封性。

5、嵌入式铜螺母:铜螺母与弹性阀门采用嵌入式接合,使二者紧密结合为一体,不因水流造成震动而产生松动或损坏现象。

6、耐腐蚀:阀体采用粉末环氧树脂涂装,可防止阀体的腐蚀及生锈,并可用于污水系统。

7、不易碎裂:以往传统铸铁闸阀常因外物击中、碰撞或重叠而造成断裂现象。由于本阀改用球墨铸铁,此种情形可大幅度减少。

8、三“O”型环密封圈:由于阀体采用三“O”型环密封圈密封设计,可减少开关时的摩擦阻力,大幅减少漏水现象及可以不停水施工更换密封圈。

9、有助生饮:由于阀体内部以无毒性环氧树脂涂装,阀板的内外表面均以橡胶完全包覆而不至于出现锈水或腐蚀现象,可供生饮。

1, Weight light: This valve uses the modular cast iron manufacture to become, the weight compares the traditional gate valve weigt to reduce 20%-30%. The installment service is convenient.

2, Flat nase type valve seat: The traditional gate valve ofter passes the laundering tulbe namely because outside the thing such as stone, water block, the cement, the iron filings, the sunclry goods and so on silts up yu fade in the scoop channel, is easy to create is unable to close dosely forms the water leakage phenomenon ,elasticity weals the gate valve base to use with the water pipe same flat base design, is not easy to create the sundry goods to silt up, unim pededy causes the fluid to be unim peded.

3, Whole en caps ulate: The valve petal uses the high quality the rubber cairy on in the whole, lagging glue, after the domestic firet-class vulc anization techndogy size, also the rubber and the modular cast iron damper ate connecting sturdily, is not easy to fall off and the elastic memory is good.

4, Fine casts the valve body: The valve body uses the precision casting, the precise geometry size causes the valve interior not to need any precision work then to phenomenon.

5, Inserts the type copper nut: The copper nut and the elastic valve inserts the type joint, causes a two in close integration with into body, because the water mobile does not create the vibration to produce becomes less crowded or the damage phenomenon.

6, Anti-corrosive:The valve body uses the powder froth epoxy resh painting may prevent the valve body the corrosion and rusts, andmay use in the sewage system.

7, Is not easy to disrupt: Former tranditional cast iron gate valve Often because of foreign collision, the collision or overlaps creates the break phenomenon, Because this valve changes to the modular cast iron, this kind of situation may langes cale reduce.

8, Three ”O ” link seal packing collar:When the valve body uses three “O” the link seal packing collar seal design, mayreduce the switch the ftiction drag, largely reduces the water leakage phenomenon and may not cut off the water supply the construction replacemert seal packing collar.

9, Is helpful to live drinks:As a result of the valve body interior vy the non-toxic epoxy resin painting, the damper plate inside and outside surface but as for does not appear the rust water or the corrosion phenomenon by the therubber complete gable, may supply to live drinks.

●主要零部件材质 Meterial Of Main Parts

序号 | 零件号码 | 名称 | 材质 | 序号 | 零件号码 | 名称 | 材质 | |

NO | Part code | Pat | Material | NO | Part code | Pat | Material | |

1 | RV-01 | 阀体 | 球墨铸铁、灰铸铁 | 10 | RV-10 | 阀杆 | 2Cr13 | |

Body | Ductile Iron, Cast iron | Stem | ||||||

2 | RV-02 | 密封圈 | NBR | 11 | RV-11 | 螺栓 | 钢制、镀锌 | |

Seal ring | Bolt | Steel,zinc-plated bolt | ||||||

3 | RV-03 | 阀盖 | 球墨铸铁、灰铸铁 | 12 | RV-12 | O型圈 | NBR | |

Bonnet | Ductile Iron, Cast iron | O-Ring | ||||||

4 | RV-04 | O型圈 | NBR | 13 | RV-13 | 止推轴承 | 青铜 | |

O-Ring | Thrust bearing | Bronze | ||||||

5 | RV-05 | 防尘罩 | NBR | 14 | RV-14 | O型圈 | NBR | |

Dust-proof cover | O-Ring | |||||||

6 | RV-06 | 固定螺栓 | 钢制、镀锌 | 15 | RV-15 | 轴盖 | 球墨铸铁、灰铸铁 | |

Fixing | Steel,zinc-plated bolt | Axle cover | Ductile Iron, Cast iron | |||||

7 | RV-07 | 传动帽 | 球墨铸铁、灰铸铁 | 16 | RV-16 | 螺栓 | 镀锌螺栓 | |

Actrating cap | Ductile Iron, Cast iron | Bolt | zinc-plated bolt | |||||

8 | RV-08 | 阀门 | 镀锌螺栓 | 17 | RV-17 | 手轮 | 灰铸铁 | |

Valve | zinc-plated bolt | Handwheel | Cast iron | |||||

9 | RV-09 | 铜螺母 | 铜 | |||||

Copper nut | Copper |

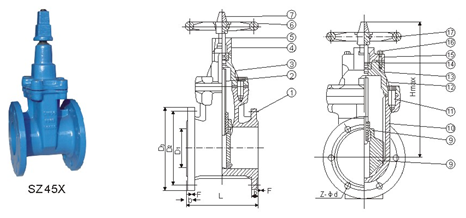

●外型尺寸,连接尺寸 Overall & Connection Dimensions

公称通径 | 尺寸 Size (mm) | |||||||||||||

DN | ||||||||||||||

Nominal diameter | L | D1 | D2 | D3 | Hmax | B | F | N-Φd | 螺栓 bolt | |||||

mm | inch | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | 1.0MPa | 1.6MPa | |||||

50 | 2” | 180 | 99 | 125 | 165 | 340 | 20 | 3 | 4-48 | M16 | ||||

65 | 2.5” | 190 | 118 | 145 | 185 | 370 | 20 | 3 | 4-48 | M16 | ||||

80 | 3” | 240 | 132 | 160 | 200 | 410 | 22 | 3 | 8-18 | M16 | ||||

100 | 4” | 250 | 156 | 180 | 220 | 450 | 24 | 3 | 8-18 | M16 | ||||

125 | 5” | 254 | 184 | 210 | 250 | 480 | 26 | 3 | 8-18 | M16 | ||||

150 | 6” | 280 | 211 | 240 | 285 | 550 | 28 | 3 | 8-23 | M20 | ||||

200 | 8’ | 300 | 266 | 295 | 340 | 630 | 30 | 3 | 8-23 | 12-23 | M20 | |||

250 | 10” | 380 | 319 | 350 | 355 | 390 | 405 | 750 | 32 | 3 | 12-23 | 12-25 | M20 | M22 |

300 | 12” | 400 | 370 | 400 | 410 | 440 | 460 | 820 | 34 | 3 | 12-23 | 12-25 | M20 | M22 |

350 | 14” | 430 | 429 | 460 | 470 | 500 | 520 | 980 | 38 | 4 | 16-23 | 16-25 | M20 | M22 |

400 | 16” | 405 | 480 | 515 | 525 | 565 | 580 | 1010 | 40 | 4 | 16-25 | 16-30 | M22 | M27 |

450 | 18” | 432 | 548 | 656 | 685 | 615 | 640 | 1270 | 44 | 4 | 20-25 | 20-30 | M22 | M27 |

500 | 20” | 457 | 609 | 620 | 650 | 670 | 715 | 1270 | 46 | 4 | 20-25 | 20-34 | M22 | M36 |

600 | 24” | 508 | 720 | 725 | 770 | 780 | 840 | 1390 | 54 | 5 | 20-30 | 20-41 | M27 | M27 |

注:DN50-600mm法兰钻孔按GB/TI7241.6标准制造,DN50-200mm法兰外径(D3)依PN10/16标准制造,DN250-500mm则符合PN16标准,DN600mm法兰外径(D3)1.0MPa符合JISG5527-7.5k标准,1.3MPa符合PN16标准。

Note :DN50-600mm flange drilling per GB/T1724.6. For the outer diameter (D3) of the flange, DN50-200mm per PN10/16,DN250-500mm perPN16, DN600mm flange’s outer diameter(D3)1.0MPa conforms with JISG5527-7.5k ,1.6MPa with PN16.